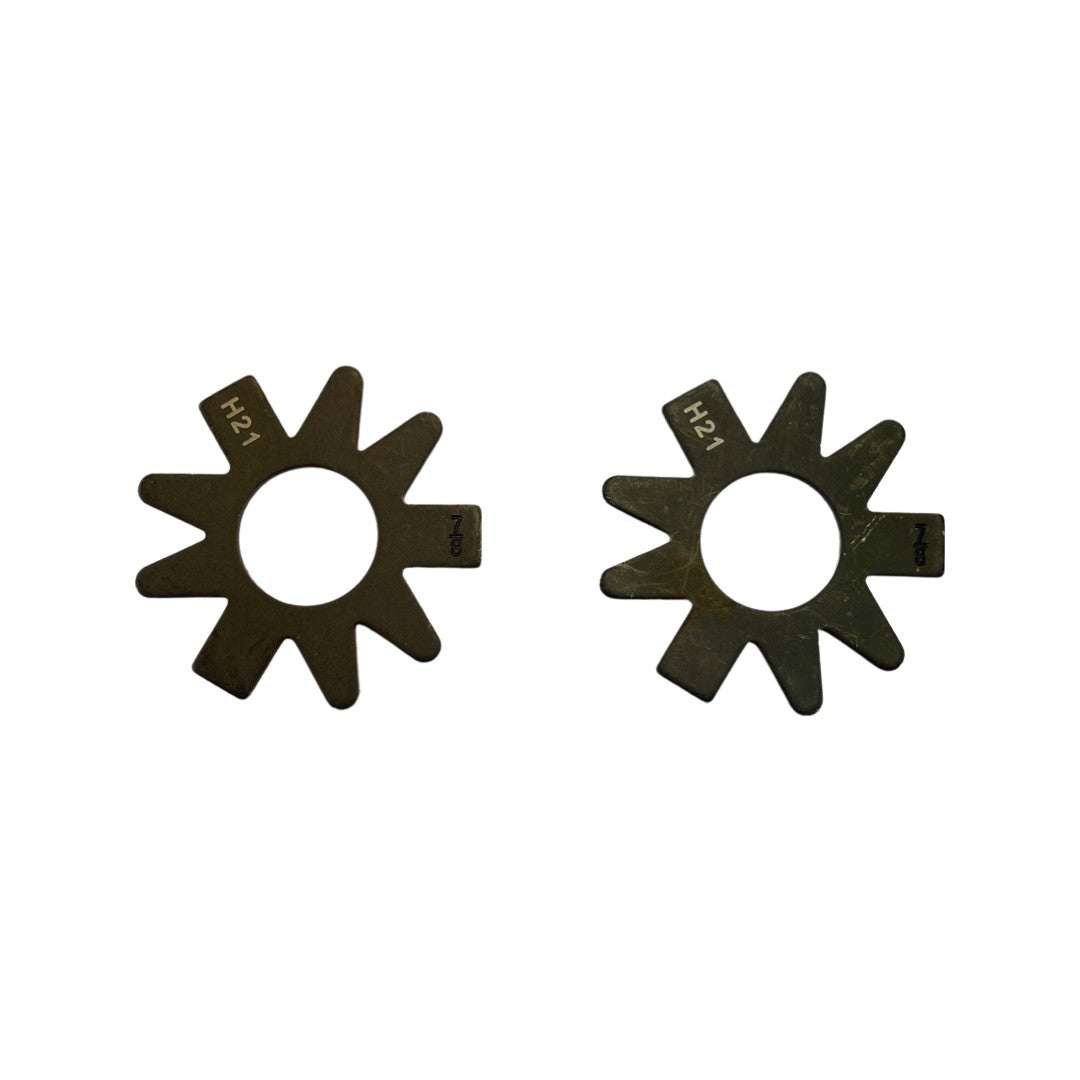

This is a complete "1 Ton" upgraded replacement FLIP KIT drag link kit for your 2007-2018 Jeep Wrangler JK. It includes the drag link (Black Aluminum ) which is also the adjusting sleeve, and left & right forged steel drag link ends, 2 Ninja Lock Washers, plus taper sleeve.

Note: taper sleeves require the knuckle drag link mount to be drilled through with a straight 7/8" drill bit.

This KIT is a 'FLIP KIT' over knuckle mount which is necessary for lifts greater than 3.5 inches. If you're looking for a STANDARD under knuckle mount, please see KIT152.

It does not include the steering stabilizer bracket which you will need to choose in the options above based on the steering stabilizer you use.

Stabilizer Relocation:

XP107 - Jeep JK Steering Stabilizer Relocation Kit

Steering Stabilizer:

XP300 - Track bar relocation bolt will not work on our 1 Ton Kits due to clearance issues.

FITMENT:

Wheels and Spacers: If you run AEV or stock Rubicon wheels, you'll need a 1.5" spacer. This kits works with a 17" wheel with a 4.75" backspacing or less.

Differentials & Mods: This steering system fits stock Dana 30/44 axles. If you have done any major modifications give us a ring at 480-470-5500 or email us at sales@apexchassis.com to discuss. This will fit most modifications, but we want to make sure before shipping. You may also want to discuss with your local Jeep shop to make sure all your modifications are compatible.

If your jeep has been upgraded to a Dana 60 axle, we have modifications that can work with that as well, just contact us to order.

What It Fits:

Jeep Wrangler JK (2007-2018).